Celotex is an insulation board that Celotex Soprema produces in the UK, and it has versatile uses. The company originated in Chicago as a branch of the Philip Carey Corporation. The company, founded in 1920, made and sold its namesake product. In 1961, Jim Walter Corporation bought the company and its assets.

A big moment came in 1998 when a lawsuit impacted the company after its products were linked to asbestos. Following this, Saint Gobain took control and continued operations. Decades later, in 2024, Soprema acquired Celotex’s production and intellectual property, making itself the brand’s primary maker. This company’s insulation boards have a lot of different functions in the construction process.

People have long touted it as one of the most well-rounded insulations in the industry. The product comes in several sizes and thicknesses depending on your needs and use. It is one of the most popular names in insulation, and a lot of professionals swear by its efficiency and reliability. Below are the key things you must know regarding this product.

What is Celotex used for?

Celotex is a general insulation board because it has many uses whether it's for floors, roofs and many more it can be adapted for all your insulation needs. It is one of the most versatile insulation in the market. Professionals can quite easily adapt the product to the needed area by just cutting it and using foil tape.

Many experts have praised the product's traits due to its water resistance, as it is a foam product. Because of this, houses that use Celotex tend to use less material for their overall waterproofing.. The other point is that it is fire-resistant as well. This means that the component slows down the spread of fire, giving extra safety to homeowners.

As mentioned, Celotex is a general insulation that has many use cases. These can include cold and warm roof situations, cavity walls between inner/outer skins and even internal wall projects. This is why many professionals and homeowners prefer this material over others. With its many uses, in many cases, it can be the only insulation that your house needs. So, let's explore this material’s main uses:

Floor Insulation

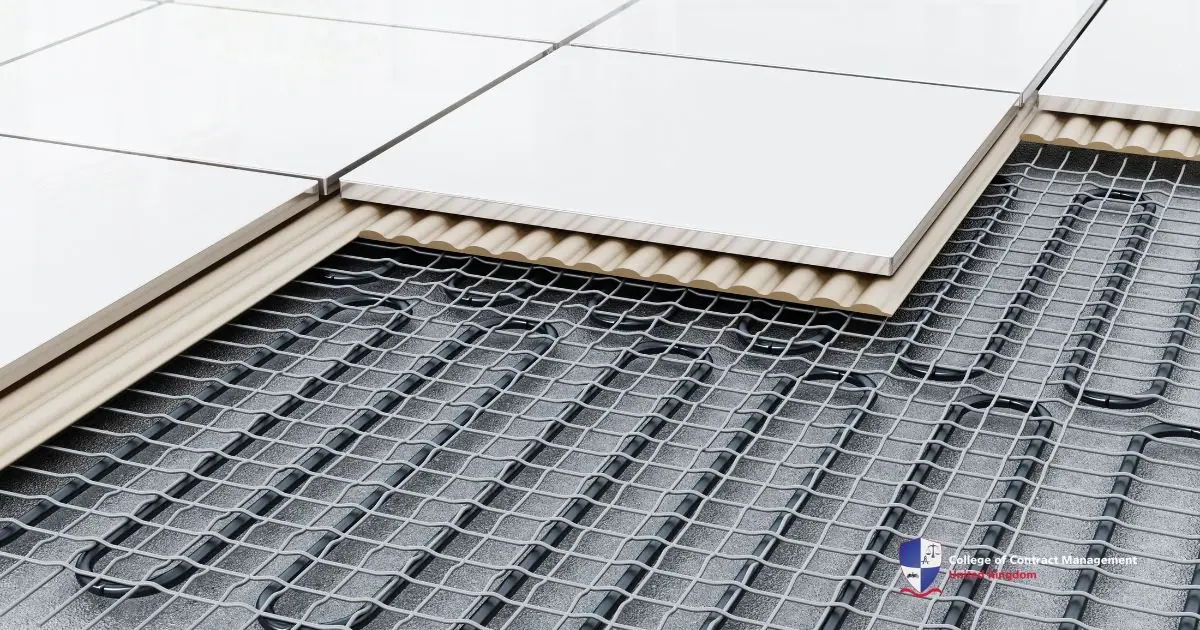

Celotex is one of the top choices when choosing the right material for the floor. This can be a perfect solution for all your flooring needs. The floor is one of the major areas that transfer heat and cold in the houses. Hence, this could prevent that from happening.

When installing it, the thing is that it should always be tight with no gaps and the seams taped together to prevent anything from leaking through. The sealing of the panel would create a perfect cover to ensure maximum effectiveness. Celotex board is the ideal insulation when installing underfloor heating as it has the additional benefit of a grid. This grid pattern makes the pipe layout much easier.

Wall Insulation

Celotex's most common use is in wall insulation. Due to its many sizes, it is highly suitable for both inside and outside of a structure. These materials have the almost perfect traits for this function with its lightweight, durable, previously mentioned water and fire resistance and highly effective at reducing heat loss.

Celotex is an all-rounder, making it suitable for new wall installation or even for rebuilding outdated insulation. Being easy to cut, this material is ideal for cavity walls, internal wall linings, and even external thermal protection systems. With its easy application, it is easier to install the plasterboard finish or brick finish, making the placement cost and time-effective.

With its range of products, the GA4000 is the go-to material for external installation due to its being a 2 in 1 product. It is a pre-bonded board and insulation, making it possible to save time and money in the process.

Roof & Loft Floor Insulation

Insulating the roof and loft floor is the easiest way to reduce heating bills and increase energy efficiency. Because of its versatility, Celotex fits between joists, allowing for boarding over the top and making the space usable as a room or for storage. However, installers must leave allowances for light fittings to prevent overheating. Additionally, these boards cannot support heavy weight and should not be used for storage or foot traffic in this situation.

Roofs are also popular for this covering system as their characteristic is ideal for roof protection. This is because not only is it a great insulator, but it is also really easy to set up. This product enables easy installation for both cold and warm applications, allowing professionals to place the board over, under, or between the roofing if necessary.

Celotex manufacturing, its material and processes

Celotex is made from polyisocyanurate foam and aluminium foil and is one of the most thermally efficient products available. The foam is sandwiched between two aluminium foil facings, and this creates quite a tough and lightweight board. The company first developed these processes in the 1920s but later sold them to Soprema. However, the process is still largely the same.

The procedure of how Celotex is made begins with the exact mixing of MDI, polyol, flame resistance, and other stuff in the presence of ingredients and a blowing agent. Afterwards, the makers pour the mixture into a facing material, allowing it to cure and expand in unison to form a continuous foam layer. They adhere facings, such as foil-paper blend or plasterboard, to the board during manufacturing, creating a fused sandwich panel. Once cured, they cut the panels to the specified dimensions.

How safe are Celotex?

Celotex is considered safe by most experts as it is non-toxic, asbestos and formaldehyde-free as well. However safety must be at the forefront of everybody's mind when doing an installation, especially with insulation. With its storied past, it has not escaped issues regarding how safe its products are. In 1998, the company had to settle a $1.2 billion settlement arising from asbestos-containing products made by both Celotex and Philip Carey. In 2017, experts blamed a disastrous fire at the Grenfell Tower in London on the cladding made by Celotex-Saint-Gobain. Despite this, most experts and homeowners still consider it safe.

The materials themselves are non-toxic, free of asbestos and formaldehyde, and not considered carcinogenic. However, it is important to note that small particles of any material can be harmful, so you should always use proper safety measures. It is recommended that you use a mask when cutting. If you cut boards in a small space, it is also good to use an air filter to avoid problems with dust.

Conclusion

Celotex is a versatile insulation solution. It is well known for its adaptability and robust performance in all aspects of insulation and processes. It's made from polyisocyanurate foam and aluminium foil that delivers incredible thermal performance, and it is water resistant and fire resistant. This makes it best suited for floor, wall, roof, and loft installation; however, it is widely used in every case of covering system. This material is non-toxic and doesn't have asbestos or formaldehyde insulation, which makes it ideal for home use.

During the installation process, there are many aspects to consider and know about. It is key for you to understand the whole process. You can gain that knowledge in the College of Contract Management to ensure that you know the future, whether it's in your professional life or even in your self-development. The CCM provides high-quality, professional courses for you to succeed in life. What are you waiting for? Join us today.